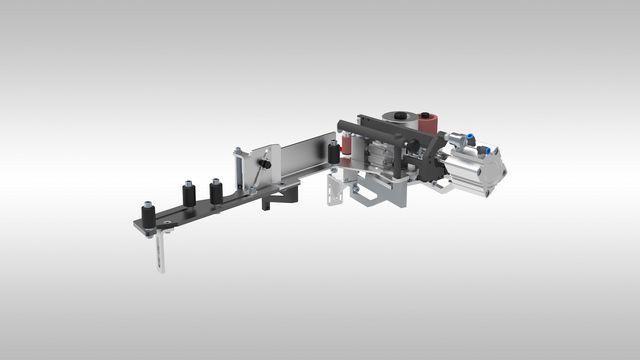

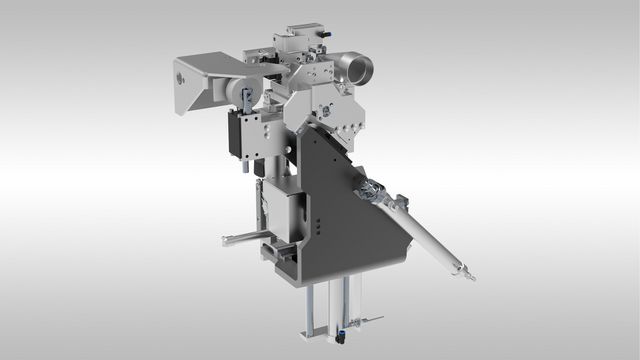

ARTEA 1030 Edgebander: Complete machining including corner rounding and 3 finishing units

The small, compact HOLZ-HER ARTEA edgebander operates with the same patented glue application nozzle also used in the larger models. The Glu Jet guarantees flexibility, exceptional edgebanding quality and simple handling.

The easy-to-clean glue system is a great added value for you right from the start.

The state-of-the-art control concept provides graphic selection capabilities - just take your pick and get going!

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the HOLZ-HER ARTEA series offers

Here is what the HOLZ-HER ARTEA 1030 offers

- PUR processing as standard feature

- Including corner rounding

- Compact with only 3,700 mm

Technical Details

We know what you need: The HOLZ-HER control

Too bad everything is not as easy to operate as our HOLZ-HER controls

With its 15.6” wide format, touch screen color monitor, the Artea edgebander is easy as pie to operate. All settings can be selected on large, interactive graphical displays. For example, direct processes can be selected on the 3D workpiece graphical display. EVA or PUR can be selected at the touch of a button and the correct processing temperature is then set automatically.

- 15.6" touch screen color monitor - standard feature

- Graphic user interface, all information displayed in plain text and/or graphic form

- Simple operation - control panel at eye height

- Programs are simple to call with program names and numbers

- Individual selection of units with the functions as basic setting possibilities for nominal values and path points

- Service reports in plain text

- Operator access with password protection

- Network-compatible

- USB for data backup

- VI.SE. Function (Digital Logbook)

Edging feed

- Roll magazine with automatic end trimming shears

- Single strip feeder (max. edging thickness 5 mm)

- Coiled edging with edging thickness up to 3 mm

- incl. roll plate with diameter of 800 mm

Jointing cutting - 50 mm

Jointing cutter unit with synchronized/counter rotation incl. 2 diamond tipped cutters. Working height of 50 mm.

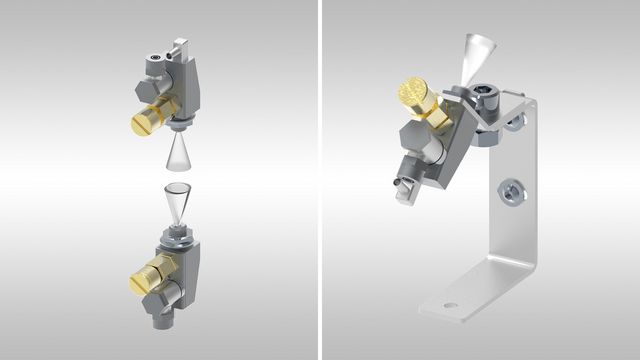

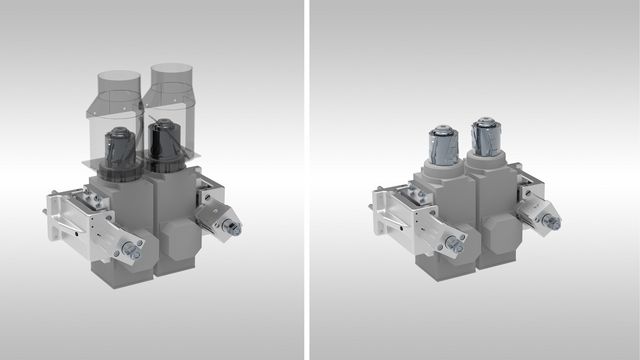

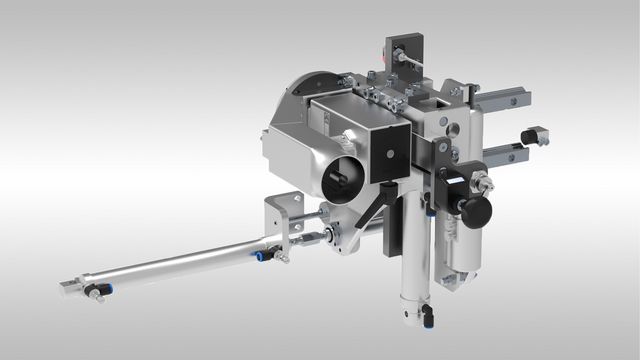

The flexible glue application system

Heat-up, glue change and cleaning require only 3 minutes each

Hardly any other glue application system offers this flexibility with such energy efficiency and cleanliness. HOLZ-HER thin film technology makes this gluing system an all rounder for craftsmen. Invisible joints with PUR glue, which can also be used in wet areas, are an obvious choice for HOLZ-HER customers.

Brilliant appearance, regardless of material - Starting with the state-of-the-art, high gloss edging right up to all standard commercial synthetic and solid wood edging. HOLZ-HER sets the trends for tomorrow today.

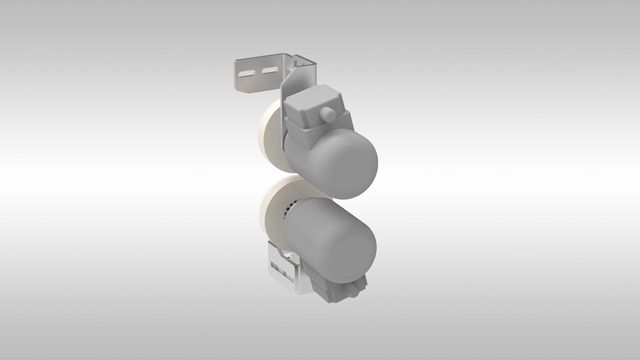

Pressure unit

High quality 2-roller pressure unit for pressing edging against panel cleanly and forcefully.

End trimming unit - 50 mm

- Heavy duty, single motor trimming unit on stable linear guide

- Optional: Radius trimming

Cutter unit

- Multifunction cutter for flush cutting up to 5 mm as well as 2 mm radius as standard feature

- Optional: Radius 1 mm | Radius 3 mm | Chamfer 45 degrees

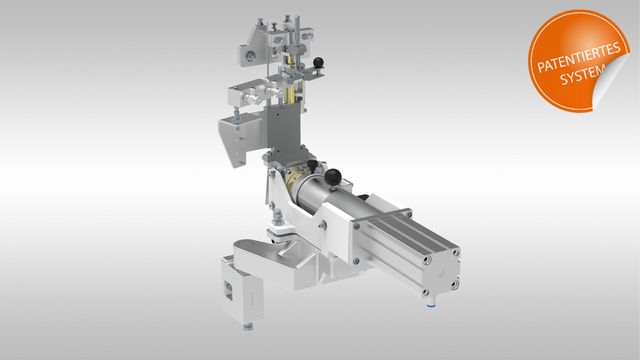

Copy cutter unit - 45 mm

Stable corner rounding unit on two linear guides

Corner rounding unit for processing corners with edge thickness up to 3 mm. Tools for radiuses up to 3 mm and chamfers up to 45 degrees.

- Diamond tipped tools for long service life

- Operating height 45 mm

- Single motor

Scraper unit for perfect finishing

- For perfect smoothing of radiuses and chamfers on plastic edging

Flat scraper

- Any glue residues are scraped off completely by the application-controlled flat scraper

Buffing unit

- Polishing for maximum gloss; for complete finishing

Front and rear spraying units

A release agent is sprayed on to a precisely defined area by special spray nozzles in the entry area. This prevents any glue or contamination residues from adhering. These glue and contamination residues are removed reliably by the spraying unit (for cleaning agent) in the discharge area in combination with the buffing unit

- Optional features for the ARTEA series

Technical Details

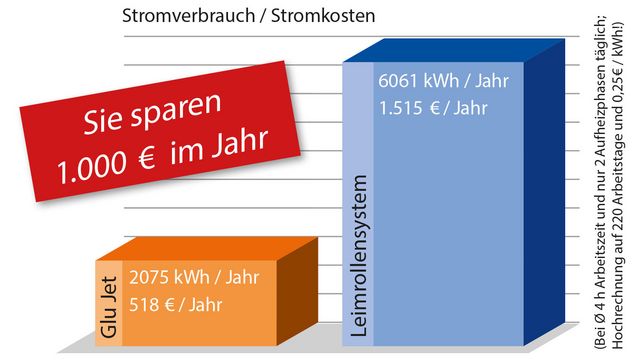

Are You Already Saving?

Are you still "rolling" glue or are you already saving? Savings of up to € 1,000 / year with our patented Glu Jet nozzle system.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

ARTEA brochure (PDF, 2 MB)