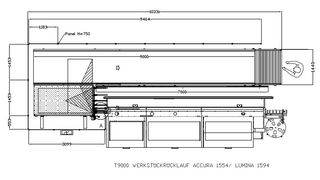

RETURN-MASTER 5920: Workpiece return for automated edge processing

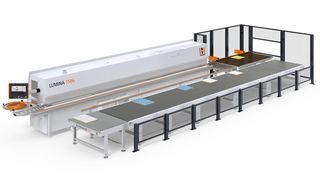

RETURN-MASTER 5920 is the perfect supplement for you edgebander - for simpler handling and higher productivity Optimally matched to your HOLZ-HER edgebander, this return feature can currently be used on all SPRINT, ACCURA and LUMINA models.

Automation is becoming increasingly important in smaller workshops to remain competitive and operate profitably. The RETURN-MASTER sets the stage for automated edgebanding, regardless of whether mass production or lot sizes of one. The HOLZ-HER RETURN-MASTER provides for efficient one-person operation for higher productivity and maximum flexibility.

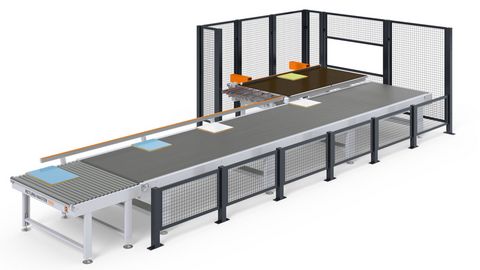

Particularly in comparison to the competition, the HOLZ-HER RETURN-MASTER ensures particularly heavy duty, stable design - compare yourself - hardly any other return mechanism in your workshop is as stable as HOLZ-HER.

Absolute quality features include the tilting air cushion table as well as the certified safety package for a secure workplace. Moreover it is easy to process special parts. The pneumatic discharge table allows even larger workpieces to be removed easily by the machine operator. Moreover the drives and guides are distinguished by their low maintenance requirements and extremely long service life. In addition to low energy requirements, a further advantage is automatic speed adaptation.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

RETURN-MASTER 5920 features:

- Workpiece lengths up to 2200 or 2800 mm

- Available: SPRINT, ACCURA and LUMINA Series

- Efficient one-man operation

- Particularly stable design

- Increased productivity

Technical Details

Stable design

Particularly in direct comparison to many competition products, the RETURN-MASTER is distinguished by its extremely stable, heavy duty design.

Certified safety package

The safety package includes an emergency shutoff linkage between the return and edgebander as well as a module for communication with the safety equipment on the HOLZ-HER edgebander. The DINA system allows monitoring of the individual drives in the overall system.

Technical Details

Energy savings made easy

The intelligent ECO Mode energy management for HOLZ-HER edgebanders not only helps preserve our environment - it also saves you money.

Maximum efficiency with Holz-Her machine networking

HOLZ-HER realizes your production ideas within 20 minutes from the first mouse click to finished furniture with seamless machine networking.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

RETURN-MASTER Brochure (PDF, 716 KB)