Machines for the production of wooden boxes and packages

Production of individual wooden packaging and wooden material boxes

Millions of goods are transported worldwide. Packaging concepts are becoming increasingly important to ensure that goods reach their destination safely. Suitable production machines and precise planning of production processes are crucial for the efficient production of wood packaging.

From the entry-level machine to the fully automatic solution, HOLZ-HER is your specialist for modern box production with wood-based materials of all kinds. More than 100 years of competence in woodworking pave the way into the future.

We help you to meet the increasing customer requirements for stable packaging materials made of wood and wood-based materials and to guarantee your customers optimum protection for the goods and packaging goods:

- Sturdy, stable crates made of different materials

- Dimensionally accurate for use in automatic high-bay warehouses

- Minimum storage volume of the crates

- Simple individual adjustments to dimensions and additional functions

- Easy assembly without tools and additional aids

- Simple disassembly without risk of damage to the packaging material

Download

Modern and individual production of wooden boxes

Solutions for packaging boxes made of wood-based materials or solid wood

The WEINIG Group offers years of experience and outstanding expertise for the packaging industry. As part of the WEINIG Group, HOLZ-HER offers optimal solutions for professional manufacturers of packaging made of wood-based materials. The competence lies in CNC machining centres, nesting CNC machines as well as in professional sawing technology. Machines for processing packaging boxes made of solid wood can be found at WEINIG Dimter.

Packaging protects and transports goods. With machine solutions from HOLZ-HER and the WEINIG Group you can offer your customers packaging of all kinds - stable, safe and in all sizes: from wooden crates, crates, push-on frames, pallets, transport shelves to special constructions for sensitive goods.

Machines for solid wood

Videos of WEINIG DIMTER Packaging days

User reports

Wood-P-Box from Wood-Form

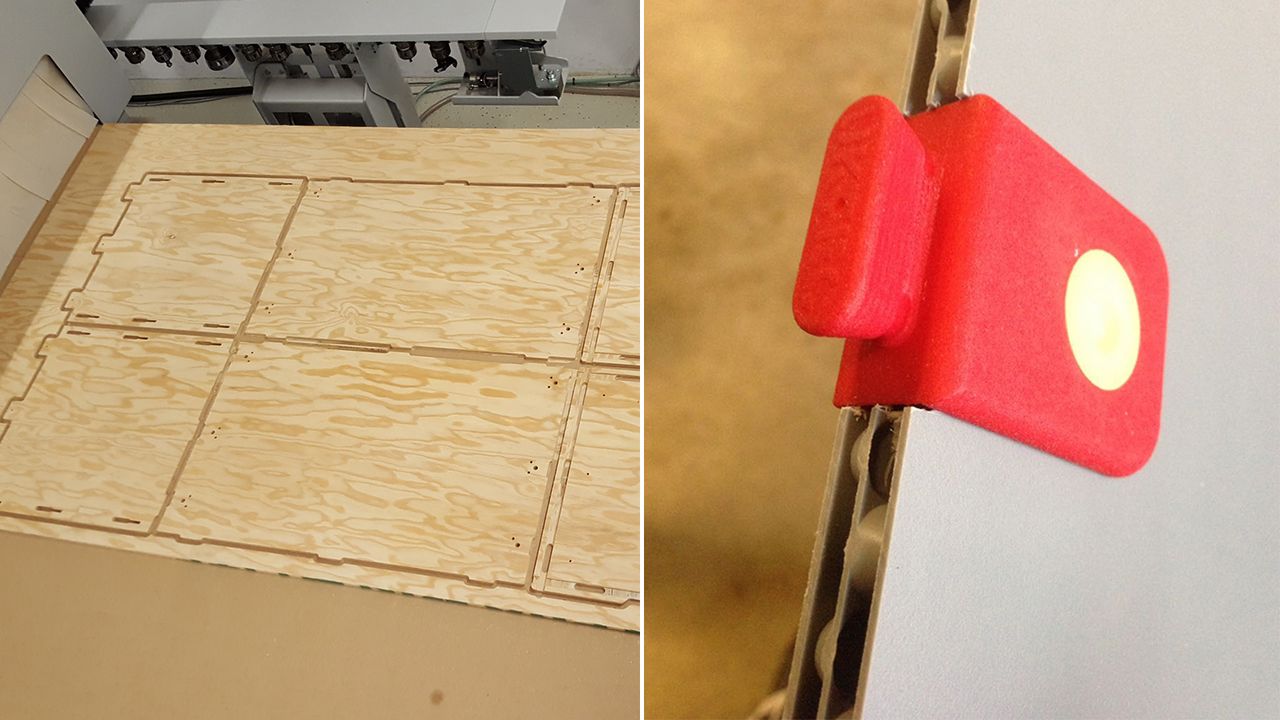

The Wood-P-Box from Wood-Form: Box production with CNC machining centres

The Wood-P-Box from Wood-Form can be manufactured with CNC machining centres and is an optimal alternative to conventional boxes due to its connector technology. Nailing crates together is a thing of the past - use the possibilities of CNC machining and innovative connector techniques for modern crate production.

The CNC production of packaging crates offers a number of advantages, which can be illustrated using the Wood-P-Box:

- Highly flexible variants for substructures and pallets: all dimensions are possible.

- Compact for transport and storage at the customer's site.

- Simple and fast: insertion of the individual side parts without additional components. This means potential savings in nails, staples, screws and, of course, manpower!

- Step by step: the product to be packaged is applied to the pallet and fastened. The housing is then placed around the product to be packaged.

- Safety: minimised risk of injury due to bevelled edges and rounded corners.

- Efficient and easy to unpack thanks to simple, positive plug-in connection.

- Additional functions, such as groove systems, handles, cut-outs, etc., can be taken into account during CNC machining.

With our HOLZ-HER CNC machines, these and similar boxes can be produced without any problems. The Wood-P-Box together results in a stable, high-precision unit and is 100% dimensionally and tolerance-accurate. Thanks to precise CNC production!

HOLZ-HER machines for packaging manufacturers

Overview of machines for the production of wooden boxes

Beam saws

The saw with the large power spectrum. The HOLZ HER pressure beam saws are the ideal cutting solution for all wooden crate packaging for even more performance, especially at high cutting rates.

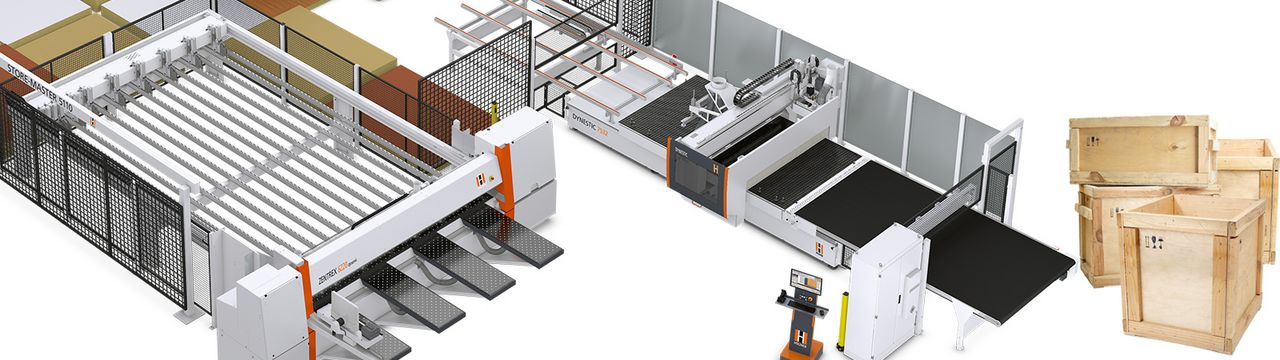

DYNESTIC Models

With the DYNESTIC models, HOLZ-HER sets standards in nesting technology. Thanks to various automation components and equipment variants, the CNC machining center is perfect for every application.

STORE-MASTER Panel Storage System

For the highest level of automation in your packaging operation. In combination with pressure beam saws and nesting CNC machines, this intelligent system guarantees highly efficient work in all batch sizes.

PRO-MASTER Models

The console machines with the latest control technology, drives and software provide almost unlimited possibilities in modern crate production.

SECTOR Panel Saws

Vertical precision in harmony with perfect ergonomics. Effective and precise: HOLZ-HER panel-sizing saws combine precision technology with intelligent optimisation and handling solutions.

NEXTEC Models

The new CNC series from HOLZ-HER revolutionises the way you will produce crates in the future and at the same time makes you fit for the challenges of the future.