Vertical panel saw SECTOR 1257: Vertical precision in harmony with perfect ergonomics

This upright panel saw allows one-man operation from panel storage to finished, precisely cut section and is appreciated for its easy moving, ergonomic design.

Even more power for your shop: The SECTOR 1257 features a powerful 5.5 kW motor and saw blade with a diameter of 303 mm. A speed-regulated motor with peak power of up to 9 kW is also available as an option.

The SECTOR 1257 is available in highly varying frame versions with cutting lengths of 4,300 mm to 6,300 mm and cutting height of 2,200 mm. The cutting depth is 80 mm. Special lengths up to 8,300 mm are available on request.

The range of applications for HOLZ-HER circular panel saws can be extended as required with genuine HOLZ-HER accessories. For example with the HOLZ-HER patented Super Cut prescoring system. This system operates with two scoring blades to score laminated panels ensuring tear-free edge quality. A further optional feature is the professional cut optimization software Opti-Base V-Cut.

Different requirements - different prices

The price of a HOLZHER machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your HOLZHER expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local HOLZHER expert will be happy to discuss all further details with you.

Here is what the SECTOR 1257 offers

- Cut optimization with Opti-Base V-Cut

- SuperCut prescoring System

- 5.5 kW motor

- Cutting Depth: 80 mm

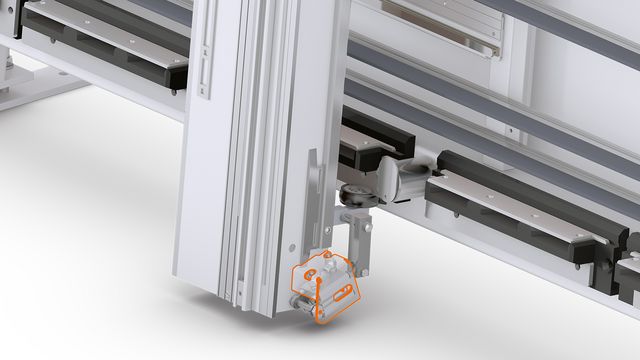

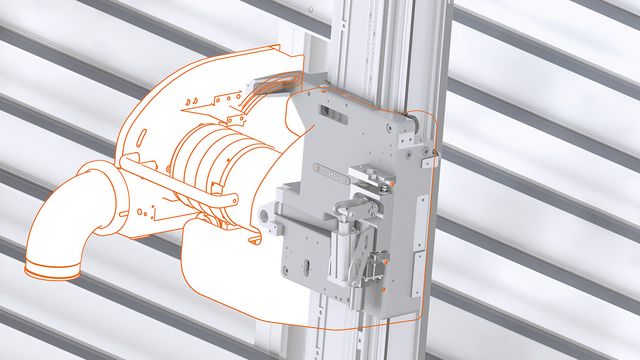

- TRK Evacuation

- 10 year guarantee on all linear guides

Technical Details

Cut optimization with Opti-Base V-Cut

Cut optimization – Step-by-step instructions for effective panel cutting

With the professional Opti-Base V-Cut cutting optimization feature from HOLZ-HER, you always get the best optimization results for perfect material utilization. Clearly arranged user surface and 10” touch screen for simple, quick and intuitive operation and management of orders, material and parts lists. The label printer for HOLZ-HER machines, which is included in the package, ensures clear identification of parts.

The way to support cutting optimization

- The optimization software for vertical panel cutting saws means you can optimize your cutting plans effortlessly.

- Waste material is significantly reduced and professionally managed through labeling.

- The choice is yours – you can either import the cutting plans created in your office via network connection / USB or enter them directly on the touch screen.

- Perfect material utilization and maximum yield thanks to intelligent software.

Your benefits

- Importing parts lists from various branch programs (Cabinet Control, Imos, OSD, CSV interface, etc.)

- Writing parts lists in the office incl. Edging / Coverings / Oversize dimensions / Production sequence / etc.

- Printing labels with all known information such as: Data Matrix Code / Com. / Dimensions / Edgings / Coverings / etc.

- Prior optimization in the office means you can get right to work on the machine.

- Monitor provides all data and indicates all work steps

- Remnants are managed and booked (remnant store also completely active)

- Programmable remnant store for panels and coverings

- Network connectivity (machine can be integrated into network so that all remnants are also known in the office and optimized results can be called up directly on machine.)

- Plug and Play

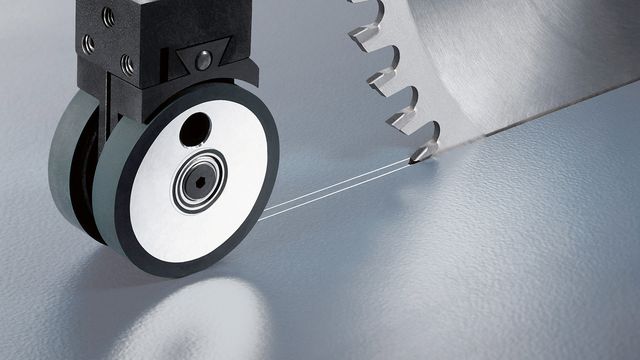

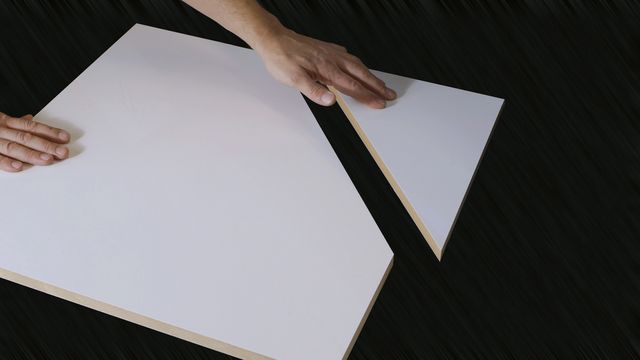

Prescoring for precision cuts

SuperCut is the patented HOLZ-HER prescoring system. It provides ready-to-glue cuts with just one basic adjustment.

- Two carbide blades score the surface of coated panels exactly to the width of the saw blade.

- The circular saw blade then cuts the panel without chipping the hard, brittle or fibrous top layer.

- The result is a smooth edge for further processing.

- SuperCut can be adjusted easily on a dimension scale.

- SuperCut can be retrofitted at any time on all SECTOR panel saws.

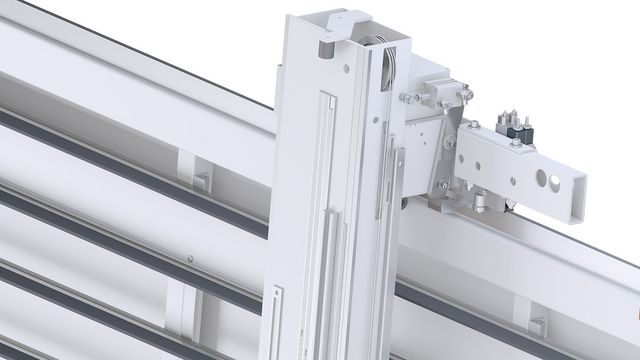

Top and bottom sawing beams

Top and bottom sawing beams with pneumatic arrest, can be operated from the control panel at the touch of a button. Including automatic interface detection for vertical cut.

Sawing Unit

The advanced sawing unit with powerful 5.5 kW motor cuts materials with a thickness of up to 80 mm effortlessly. For harder materials, an optional 9 kW motor is also available featuring integrated speed regulation, even for synthetics and nonferrous materials.

To ensure operator-friendly tool changes, the attachment can be mounted in any desired position on the sawing beam. The ProLock quick clamp chuck guarantees quick tool changes.

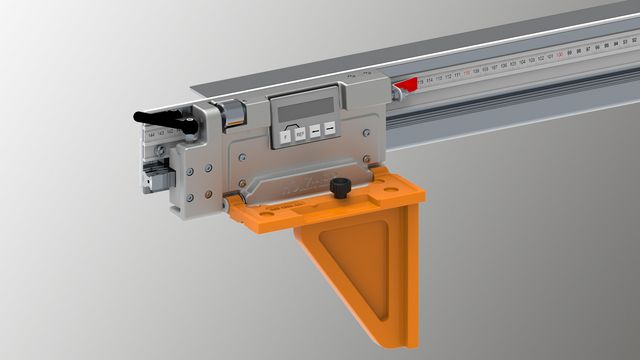

Digital horizontal cutting with motor-driven precision adjustment

The sawing unit is equipped with a pneumatic brake as a standard feature.

The dimension for the horizontal cut can be precisely adjusted to an accuracy of 1/10 mm at the touch of a button with the adjustment motor included as a standard feature. As an alternative the setting can also be read off on the setting scale.

Strip Stop

The strip stop ensures a uniform cut to the width of the workpiece. Once set - every cut is the same

Longitudinal stop with scale

Longitudinal stop with setting display above scale for vertical cut. Guided by hardened linear guide.

Digital longitudinal stop with fine adjustment

Digital dimension display for vertical cut, including fine adjustment of hardened linear guide (optional).

GeoMetric angle cutting attachment

The mobile angular cutting device allows angular cuts up to 45° to be completed easily. For this purpose simply clamp the angular cutting device to the saw and set the angle in degrees. Two adjustable vacuum units hold the panel in place. Then cutting can be accomplished in the vertical or horizontal direction. A simple conversion feature allows the angular cutting unit to be attached on the left or right side of the cut.

Single-company quality – from steel plate to finished machine

In house production of frames for vertical panel saws

Up to 2200 tons of steel and aluminum are used in HOLZ-HER's own frame construction. A laser cutting unit with fully automatic charging optimizes cutting steel plates with thicknesses up to 25 mm. This ensures that HOLZ-HER can use the ideal material thickness for all construction parts where rigidity is relevant.

With a nominal pressing force of 400 tons, multiple hydraulic trimming presses ensure perfect component shape with automatic material thickness measurement and pressure control.

The individual parts are welded together very carefully. Optimally designed welding equipment ensures high quality consistency for your machine.

The completely welded frames are milled with high precision on a number of long-bed cutting machines. This ensures that all surfaces are optimally prepared for later attachment of guides and equipment.