Beam saw TECTRA 6120 Series: The adaptable panel saws with the high performance spectrum

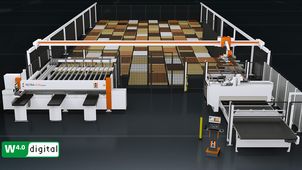

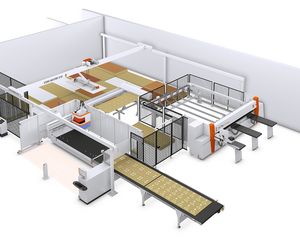

In times of highly specific customer requirements and low production quantities, custom solutions are required to achieve the synergistic effects of horizontal panel saws combined with intelligent charging equipment. As with the TECTRA 6120 lift, charging is possible using an integrated lifting table system or on the TECTRA 6120 power, direct charging to the machine from a horizontal storage facility. For maximum performance requirements, the TECTRA 6120 dynamic model allows the pressure beam saw to be charged with new panels from storage even while the previous cutting operation is still in progress, without interrupting the current sawing cycle.

Thanks to its high acceleration values and feed rates, the horizontal panel saw TECTRA 6120 can process even large quantities of panels rationally. This versatile saw is available with various cutting lengths and cutting widths, allowing it to be adapted to highly varying applications as a custom solution.

All machines

HOLZ-HER TECTRA 6120 classic

The saw with the high performance spectrum

- Saw Blade Protrusion up to 82 mm

- Sawing Unit: up to 11 kW

- Cutting Lengths: up to 4,400 mm

- Cutting Widths: up to 4,300 mm

HOLZ-HER TECTRA 6120 power

The saw with the high performance spectrum

- Saw Blade Protrusion up to 95 mm

- Sawing Unit: up to 15 kW

- Cutting Lengths: up to 4,400 mm

- Cutting Widths: up to 4,300 mm

HOLZ-HER TECTRA 6120 lift

The space-saving lift solution, including elevating table

- Solid lifting table as standard feature

- Saw Blade Protrusion up to 95 mm

- Sawing Unit: up to 15 kW

- Cutting Lengths: up to 4,400 mm

- Cutting Widths: up to 4,800 mm

HOLZ-HER TECTRA 6120 dynamic

Completely prepared for dynamic charging

- Prepared for charging solutions

- Saw Blade Protrusion up to 95 mm

- Sawing Unit: up to 15 kW

- Cutting Lengths: up to 4,400 mm

- Cutting Widths: up to 6,500 mm

Here is what the HOLZ-HER TECTRA series offers

References

![Two story panel storage system from HOLZHER: Custom designed STORE-MASTER Reference customer for STORE-MASTER panel storage system from HOLZ-HER, Alpiger Holzbau AG [Alpiger Woodworking Co.]](/fileadmin/_processed_/b/b/csm_StoreMaster-Plattenlager-Referenzkunde-Alpinger-CH-01_a4b70ac13a.jpg)